EXPERTISE

Stewarts work extensively with a large proportion of our clients in customising designs and configurations.

We are well equipped to reproduce any “special” valve or manifold manufactured in the past. We will also work with any client in tailoring and producing a precision product with any number of valves; configured to meet the specific requirements of the system.

STEWARTS Valves & Manifolds have been designed to provide the safest possible connection and mounting of instruments.

All threaded connections are High Tolerance NPT.

Materials

- 316L Stainless Steel (UNS S31600 / S31603)

- MONEL® 400 (UNS N04400)

- HASTELLOY® C-276 ® (UNS N10276)

- INCONEL® 625 (UNS N06625)

- INCOLOY® 825 (UNS N08825)

- TITANIUM Gr.2 (UNS R50400)

- DUPLEX (UNS S31803)

- SUPER DUPLEX (UNS S32760)

- HASTELLOY® C-22 (UNS N06022)

- SUPER AUSTENITIC ST.ST 6%Mo (UNS S31254)

Note: Other materials available on request.

POSITIVE MATERIAL IDENTIFICATION (PMI)

PMI Testing enables a component’s material grade or chemical analysis to be found. PMI testing is one of the more specialized non-destructive testing methods. With PMI Testing the alloy composition of materials can be determined. If a material certificate is missing or it is not clear what the composition of a material is, then PMI Testing offers the solution.

PMI Testing is particularly used for high-quality metals like stainless steel and high alloy metals. While engineers push the boundaries of material capacities to their limits in the design, assurance that the proper material is used becomes ever more important.

Using our X-ray fluorescence (XRF) analyser we can carry out non-destructive Positive material identification (PMI) to provide highly specific material chemistry to rapidly and accurately identify alloy grades and pure metals.

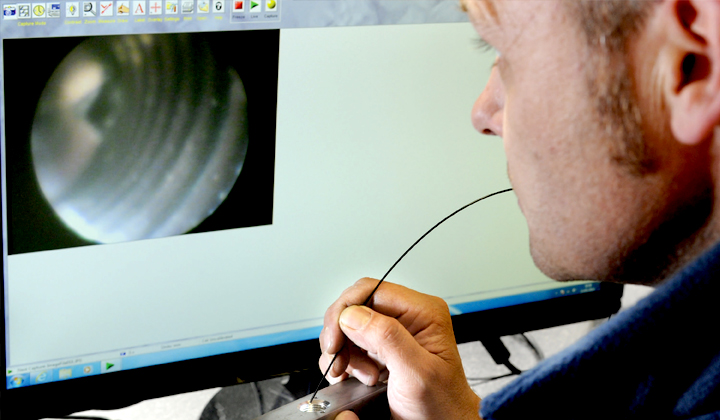

VIDEO BORESCOPE INSPECTION

STEWARTS use a Flexible Video Borescope for non-destructive visual inspection.

This allows for an internal visual inspection for burrs, defects, surface finish irregularities in our valves and manifolds.